-

- HOME

-

CORPORATE

- CORPORATE

- ABOUT US

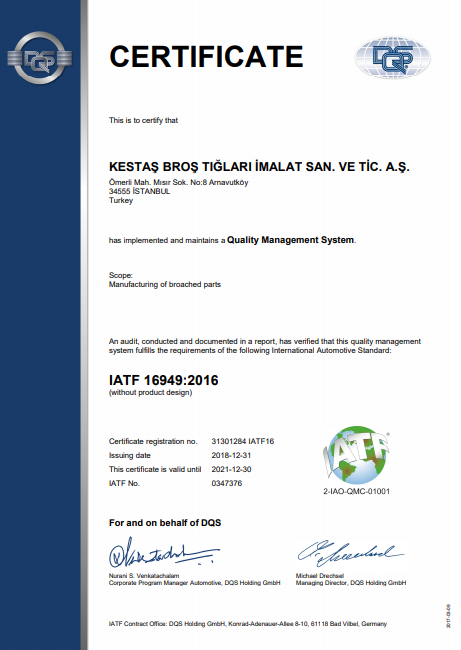

- CERTIFICATES

- CAREERS

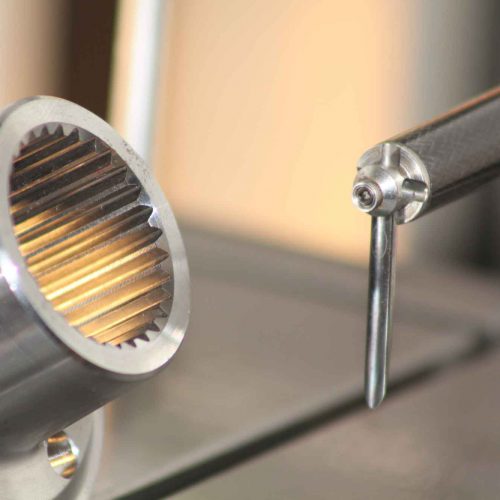

- PRODUCTS AND SERVICES

- BÜLTENLERİMİZ

- REFERENCES

- CONTACT

-

English (UK)

- English (UK)

- Türkçe