Our company, which provides broaching tools and broaching machines to its customers who apply broaching operation to its own products, has been providing broaching service for mass production under the roof of Kestas for many years

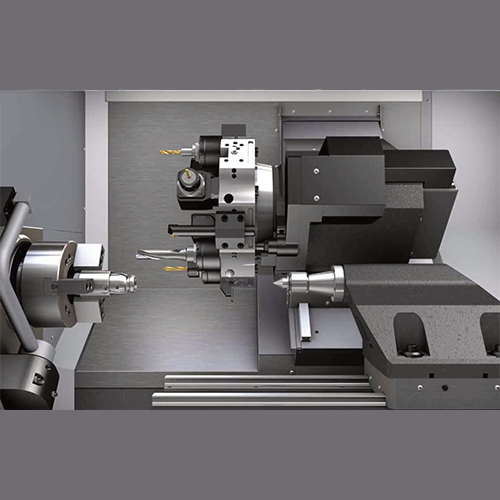

Our company has become an indispensable solution partner of its customers by producing “Quality, Fast and Cheap Production Techniques with Broaching Method” to reduce the production costs with constantly expanding broaching line and CNC processing line which is currently active by undertaking the cost of broaching tools and fixtures.

Producing “finished parts” by performing all of the machining processes of the parts including broaching operation under the roof of Kestas provides great advantages to our customers in terms of logistics and cost.

Our company has been awarded the IATF 16949: 2016 Automotive Quality Management System certificate by establishing the documentation system and quality control mechanisms that must be prepared during the processes within the scope of automotive standards of the sub-industry customers that directly produce parts to the main industry, and completed the optimization of the product broaching and part manufacturing line to meet these needs.